This accident reinforces the importance of auditors inspecting the evidence collected during an audit to ascertain whether the requirements are being met, specifically conformance with the relevant standards,” Dr Godley said. “Audits are essential for independently verifying the effectiveness of an organisation's processes and procedures. The investigation also found the maintenance organisation had limited internal independent oversight and increased reliance on audits for the evaluation of its quality performance. In addition, in the years leading up to the accident, staff changes reduced the maintenance provider’s levels of qualifications and experience. The investigation noted that in the weeks prior to the accident the maintenance company was experiencing a period of very high workload that likely exceeded the workforce’s capability and reduced the chief engineer's capacity to oversight maintenance activities. “Maintenance organisations are urged to consider the human factors elements associated with their practices, capture them in their documented quality control procedures, and ensure they are complied with.” “This investigation highlights the limitations of verbal communication as a method of explaining and understanding problems and their unreliability as a means for capturing essential tasks over an extended time period,” Dr Godley said. Instead, it had adopted a number of work practices that increased the risk of memory-related errors and omissions, including using abbreviated inspection checklists, not recording all flight control disturbances, and not progressively certifying for every inspection item as the work was completed.

The investigation also found that the maintenance organisation had not recorded and tracked all maintenance activities for the overhaul as the work progressed over a period of almost four months. “Different scenarios were examined for the cause of the bolt separation however, as it was not possible for the helicopter to operate for any length of time without a nut attached to the bolt, it was likely that the nut was not reinstalled or inadequately torqued during the helicopter’s recent 2,200-hour overhaul,” Dr Godley said. After re-examining the helicopter wreckage, the bellcrank and a bolt, later confirmed to be from the missing fastener, were recovered from the wreckage site and examined by the ATSB.ĪTSB Director Transport Safety Dr Stuart Godley said the separation of the bolt would have resulted in the main rotor disc tilting back beyond its normal operating limits and striking the tailcone. The ATSB’s investigation subsequently identified that a fastener – a bolt and self-locking nut – which connected the helicopter’s cyclic assembly’s horizontal push-pull tube to a bellcrank, was missing. The wreckage of the R22 was subsequently located about 7 km to the north-north-west of the airport. About fourteen minutes after take-off witnesses observed a plume of smoke in the general direction of the helicopter’s path. The R22 had departed Cloncurry Airport, north-west Queensland, on 2 August 2017, on a ferry flight to reposition for aerial mustering after having undergone a major overhaul. Voluntary - REPCON Rail Confidential Reporting SchemeĪ self-locking nut that was likely either not reinstalled or inadequately torqued during maintenance, allowing a bolt to separate from a bellcrank in a Robinson R22’s cyclic control in-flight, resulted in the helicopter’s unrecoverable loss of control and collision with terrain, fatally injuring the pilot.Mandatory - Rail accident or incident notification.Voluntary - REPCON Marine Confidential Reporting Scheme.

Mandatory - Marine accident or incident notification.Marine safety investigations and reports.

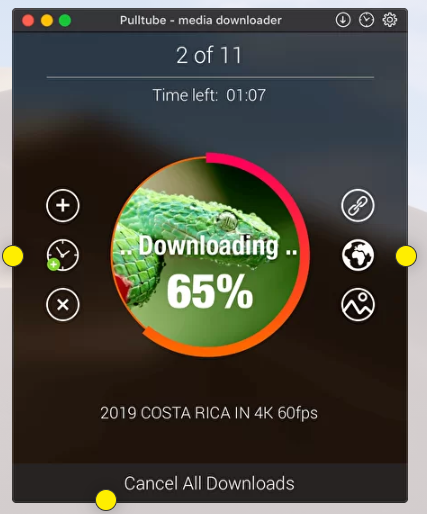

#Pulltube crashing verification#

0 kommentar(er)

0 kommentar(er)